Description

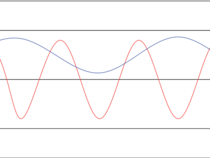

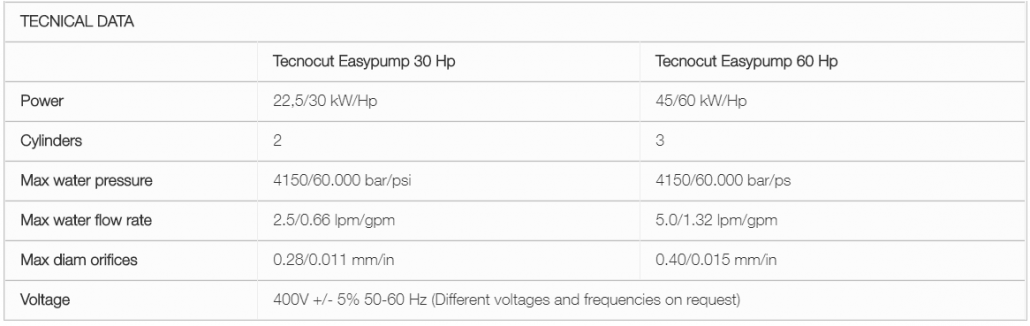

CMS has developed a new concept of high-pressure intensifiers: two or three parallel, independent and electronically synchronized pressure multipliers, which deliver a constant pressure while eliminating the need of an attenuator, a typical feature of old, traditional intensifiers.

- highly constant pressure without using any attenuator

- higher stability of the dynamic pressure signal to guarantee superior quality cut

- lower wear of all machining centre high-pressure circuit components, longer duration of materials and reduction in maintenance interventions

- the configuration with three independent cylinders allow to disable any one of them that requires maintenance, thus keeping the intensifier running and avoiding to shut down the cutting system

- software-based electronic control of cutting pressure

- hydraulic pump with fixed flow rate

- hydraulic cylinders return circuit managed by nitrogen accumulators

- water/Oil exchanger for hydraulic circuit cooling

- specific for CMS cutting systems.

- the 60HP model comes with 2 motors (in order to work 30+30 HP)

Advantages

CONSTANT OUTPUT PRESSURE FOR BETTER CUTTING QUALITY

Hydraulic intensifier with 2 or 3 independent and electronically syncronized parallel cylinders to guarantee a constant signal of output pressure without the use of attenuator.

REDUNDANT ARCHITECTURE: LESS MACHINE DOWNTIME

The technology with 3 independent cylinders allows the bypass of a single cylinder that needs maintenance, while the machine is working, avoiding unnecessary downtime.

LESS MAINTENANCE COSTS

The parallel cylinders architecture is designed for a low cycle frequency that reduce the high pressure components wear and consequently the maintenance costs.

“NOISELESS” SYSTEM FOR A QUIET ENVIRONMENT

Sealed cover with soundproof panels to guarantee high noise reduction while the intensifier is working.