Description

Control unit Edge Control BC 15 with 15.6″ touch screen

- Colour screen 16:9

- Powerful control system with simple graphic operation

- Rotating and tilting control panel at eye level

- Network-compatible

- Operator access with password protection

- Quick setting between PUR and EVA

- VISE function

Vi.se. (VIsual SEtting mode)

VISE provides all setting values for the digital counters and pressure gauges as a digital logbook to set up the machine quickly and safely.

The display is interactive via the 15.6″ touch control panel.

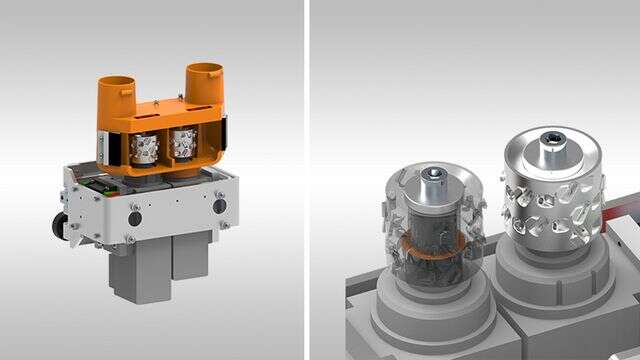

Jointing cutter unit – 45 (60) mm

Cut edgings often have small tears in the top layer. The jointing cutter unit ensures perfect glued surfaces and prepares the panels for the gluing process.

For perfect edge appearance and top quality, all HOLZ-HER edgebanders are equipped with diamond tipped cutters with integrated chip evacuation as well as high concentricity and long service life. The jointing cutters have patented purging holes to effectively prevent double machining, thus increasing the service life significantly. In addition a height adjustment feature is included for optimum utilization of the cutters.

- Optionally available with working height of 60 mm.

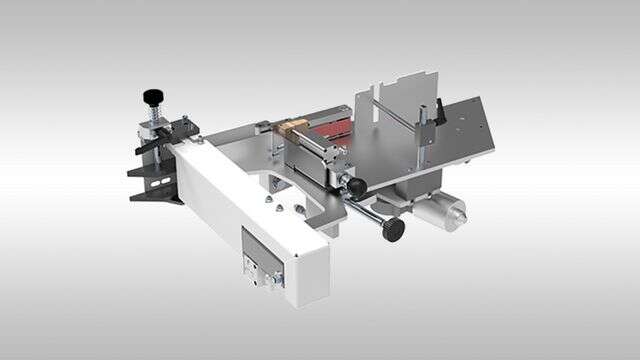

Edging feed

Fully automatic, user-friendly feeder for coiled edging as well as single strip feeder. Gentle material handling with transport belts for edging transport and automatic edge recognition.

An edging separator is available (as an option) for practical processing of packages of edging strips.

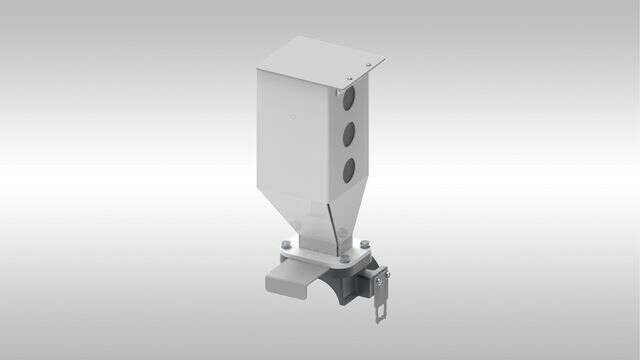

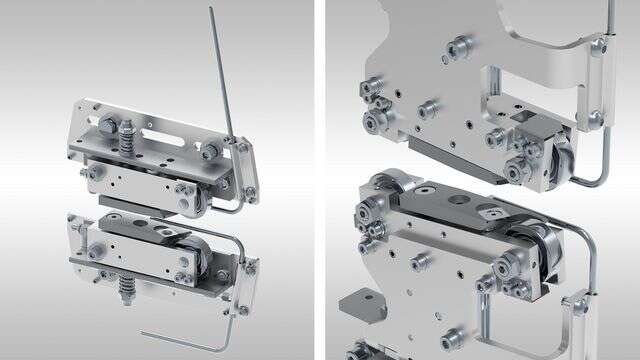

Pressure unit

High quality 3-roller pressure unit for pressing edging against panel cleanly and forcefully. First roller motor-driven, two subsequent pressure rollers.

Pneumatic, application-controlled pressure unit (optional).

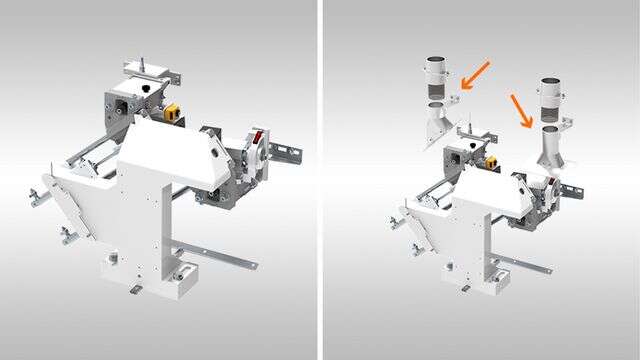

The most flexible glue application system on the market

Heat-up, glue change and cleaning require only 3 minutes each

No other glue application system offers this flexibility with this energy efficiency and cleanliness. HOLZ-HER thin film technology makes this gluing system an all rounder for craftsmen and industrial users. Invisible joints with PUR glue, which can also be used in wet areas, are an obvious choice for HOLZ-HER customers.

Starting with the state-of-the-art, high gloss edging right up to solid wood edging with extremely high cross sections, HOLZ-HER remains unequaled in terms of appearance, regardless of the material. HOLZ-HER sets the trends for tomorrow today.

Trimming unit – 60 mm

For straight or chamfered trimming on thin edging; unit pivots manually to 10 degrees.

- With 60 mm working height, pivots pneumatically.

High quality version with stable cast stand and two sawing motors each on two guides.

Cutter unit

Multifunction cutter unit for flush cut on edging with thickness up to 6 mm, radiuses up to 3 mm.

Including quick adjustment flush / radius as well as diamond tipped tools.

Scraper unit for perfect finishing

Perfect finish – generous finishing area.

- For perfect smoothing of radiuses and chamfers on plastic edging.

Flat scrapers

With plunge control

- Perfect finish – generous finishing area

- The application-controlled flat scraper removes all glue residues, which are then blown off the panel by the integrated blast nozzles

With pre and post-sensing (optional)

- Clean surface finishing with pre- and post-sensing for high feed rates

Buffing unit

Perfect finish – generous finishing area.

- Polishing for maximum gloss; for complete finishing.

Reviews

There are no reviews yet.